Exploring the Basics of Robotics

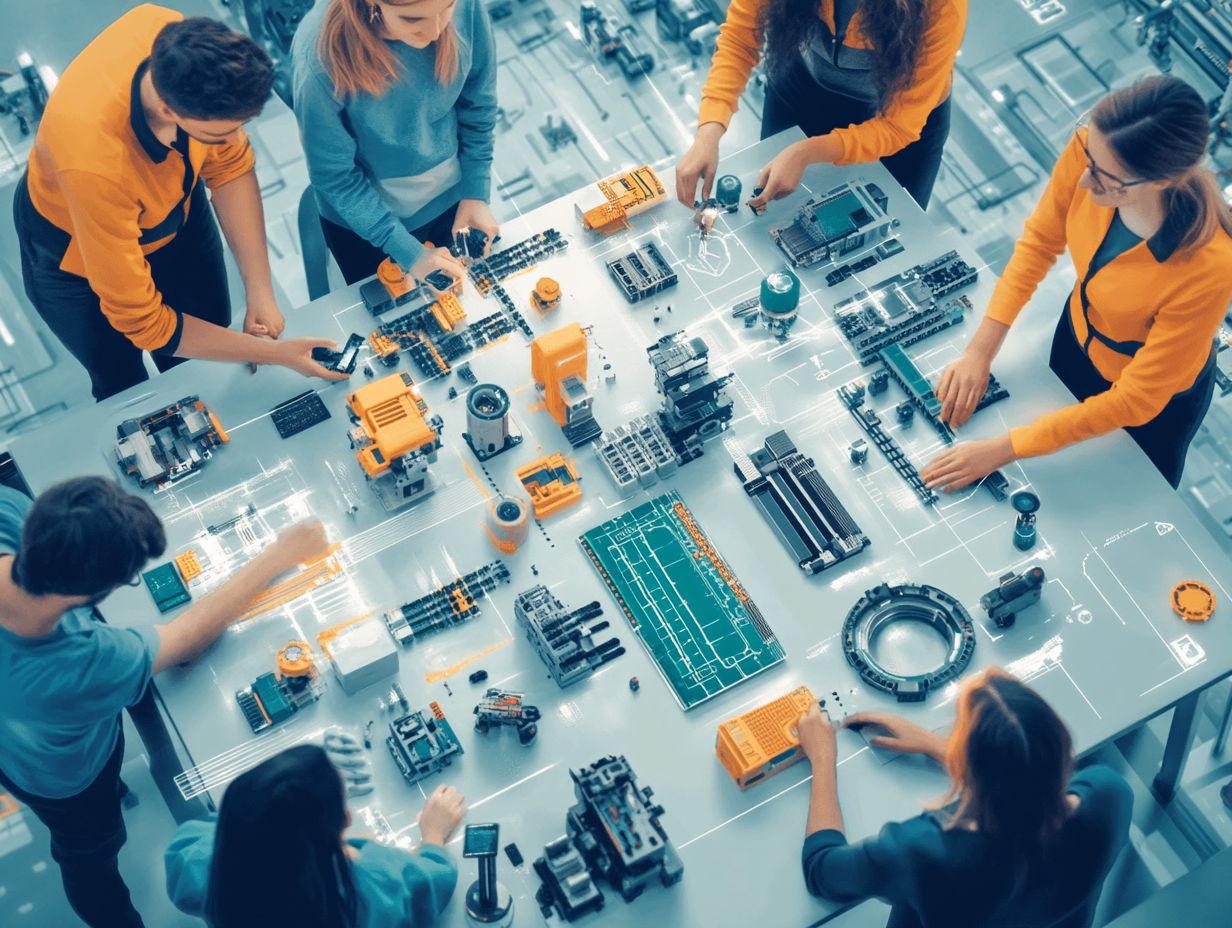

Robotics is a dynamic field that seamlessly blends engineering, computer science, and innovation, crafting machines capable of performing tasks either autonomously or in collaboration with humans.

This article invites you to explore the captivating world of robots beginning with an understanding of what they are and a brief glimpse into their history, before delving into the diverse types, ranging from industrial to service robots.

Get ready to discover the essential components that constitute these remarkable machines and learn about their varied applications across industries such as manufacturing, healthcare, and research.

Embark on this journey as you uncover the intricacies of robotics and its profound impact on our future.

Contents

Key Takeaways:

- Robotics involves designing, building, programming, and using robots.

- The three main robot types are industrial, service, and collaborative.

- Robots are made up of sensors, actuators, and control systems working together.

What is Robotics?

Robotics stands as a fascinating interdisciplinary field that seamlessly merges engineering, computer science, and technology to design, build, and operate robots capable of performing tasks either autonomously or with human oversight.

This innovative domain boasts a myriad of applications, from healthcare robotics, where robots play crucial roles in surgeries and rehabilitation, to autonomous robots adept at navigating their environments independently.

As interest in robotics education continues to soar, it cultivates a vibrant community, inspiring the next generation of robotics engineers.

With every advancement in robotic technologies, the scope of this field broadens, significantly impacting various industries and enhancing the quality of our everyday lives.

Now, let s take a brief look at the history behind this exciting field.

Brief History of Robotics

The history of robotics stretches back centuries, with early ideas of automated machines popping up in ancient civilizations. However, it truly gained traction in the 20th century, thanks to groundbreaking advancements in engineering and computer science, particularly at prestigious institutions like MIT and Carnegie Mellon University.

During this transformative period, pioneers began their journey to create the first industrial robots, completely revolutionizing manufacturing processes and significantly boosting efficiency. The arrival of Unimate, the first mass-produced industrial robot, in the 1960s marked a crucial turning point.

The contributions from the Japanese Institute of Technology in the 1970s further accelerated the evolution of robotic systems, setting the stage for enhanced automation and precision across various industries.

As these institutions engaged in both collaboration and competition, they laid the foundation for today’s robotic technologies, which now span everything from autonomous vehicles to advanced medical robots. This rapid evolution continues to shape the future, offering exciting possibilities just around the corner.

Types of Robots

You ll find a diverse array of robots, each carefully designed for distinct tasks and applications.

Industrial robots, for instance, are engineered to streamline manufacturing processes with remarkable efficiency.

Service robots are designed to assist in sectors like hospitality and healthcare, providing invaluable support.

Collaborative robots, also known as cobots, work hand in hand with humans, significantly enhancing productivity in various environments.

Industrial Robots

Industrial robots are your go-to automated machines, revolutionizing manufacturing processes by boosting productivity, precision, and efficiency through programmed tasks like welding, painting, and assembly.

These sophisticated systems leverage cutting-edge robotics technologies, including artificial intelligence and machine learning, allowing them to adapt effortlessly to various operational demands. This ensures they integrate seamlessly into your existing workflows.

By taking on repetitive and labor-intensive tasks, industrial robots significantly minimize the risk of human error and enhance workplace safety. Their capacity to operate continuously without fatigue maximizes output, making them essential in today s engineering landscape.

Implementing these automated solutions not only streamlines your production lines but also leads to cost savings and improved product quality, ultimately driving innovation in the manufacturing sector.

Service Robots

Service robots are designed to assist you in a variety of tasks. They help with everyday chores, intricate healthcare applications, and even offer companionship when needed.

These innovative machines have made remarkable progress in home settings. They can vacuum floors, wash windows, or whip up meals, significantly lightening your daily responsibilities.

In the healthcare realm, advancements like robotic surgical systems and telepresence robots are transforming patient care. They enhance surgical precision and facilitate remote consultations at your convenience.

Projects like robots that can help care for elderly people showcase how technology can provide companionship and aid in managing daily needs with dignity.

In the hospitality industry, service robots check in guests, transport luggage, and ensure swift room service. This ultimately elevates customer satisfaction and boosts operational efficiency.

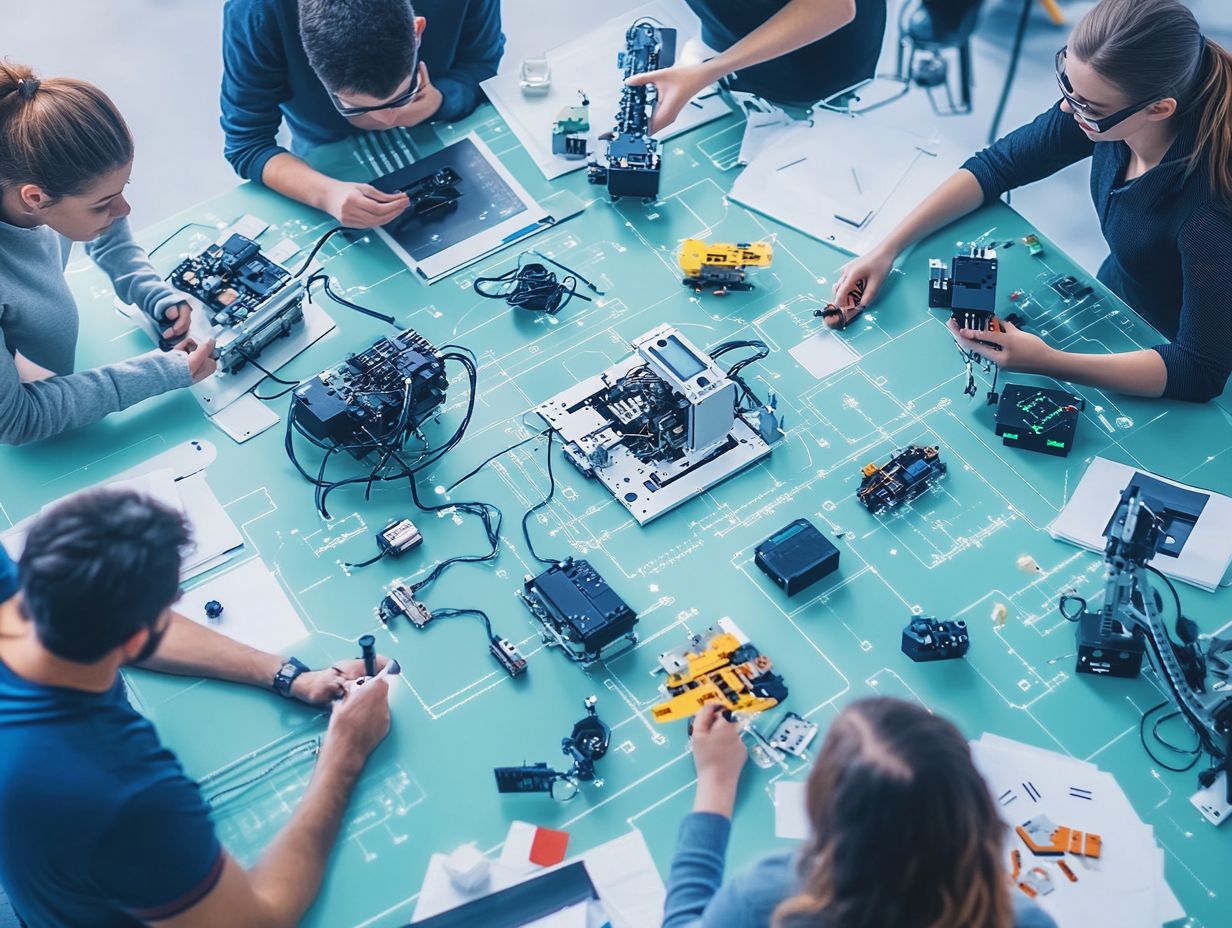

Collaborative Robots

Collaborative robots, or cobots, work seamlessly alongside you. They enhance workplace safety and productivity by assisting with tasks that require human intelligence and robotic precision.

These machines are being integrated into various sectors, including manufacturing, healthcare, and logistics. Their ability to collaborate with human workers significantly reduces repetitive strain injuries.

By tackling physically demanding tasks, cobots allow you to focus on more complex and creative responsibilities. This effectively transforms your job role.

As industries quickly embrace cobots, they streamline workflows, optimize production timelines, and cultivate a more flexible workforce ready to adapt to changing demands.

Collaborative robots create a harmonious workplace that fosters innovation and enhances your overall job satisfaction.

Components of a Robot

Robots consist of three key parts: sensors to gather information, power systems to energize them, and programming that tells them what to do.

Sensors and Actuators

Sensors and actuators are vital components of robots. Sensors collect data from the environment, allowing robots to interact intelligently with their surroundings. Meanwhile, actuators, which help the robot move, transform signals into physical movements.

These devices are crucial for ensuring that robots execute tasks with precision and adaptability. For example, ultrasonic sensors measure distance, giving robots the power to navigate obstacles with finesse.

On the actuator front, motors and servos convert electrical signals into motion, facilitating actions such as lifting or rotating components. The synergy between sensors and actuators enhances robot functionality and signifies remarkable advancements in robotic applications.

Power and Control Systems

Power and control systems are fundamental to robot operation. They deliver essential energy to components and govern actions based on sensor input.

These systems can be categorized into hydraulic, pneumatic, and electric power systems, each serving specific functions that enhance operational capabilities.

Hydraulic systems utilize pressurized fluid for powerful and precise control, making them ideal for heavy-duty applications. In contrast, pneumatic systems harness compressed air, resulting in lightweight designs perfect for rapid, repetitive tasks.

Electric power systems dominate modern robotics, providing versatility and efficiency. They often integrate seamlessly with advanced control algorithms to optimize performance.

Together, these power systems make robots faster and more efficient, which is exciting for all sorts of applications. They significantly influence a robot’s speed, accuracy, and energy consumption, ultimately enhancing its effectiveness in real-world situations.

Programming and Intelligence

Programming and intelligence form the backbone of robotics, enabling robots to tackle complex tasks using different programming languages and methods that mimic intelligent behavior.

As these machines navigate diverse environments, your choice of programming languages is critical for their design and functionality. Python, C++, and ROS (Robot Operating System) are particularly favored for their versatility and robustness.

Python shines for its simplicity and extensive libraries, making it easy to implement machine learning techniques. C++, on the other hand, delivers the speed and performance essential for real-time processing.

When you integrate artificial intelligence algorithms, robots gain the remarkable ability to learn from their surroundings, adapt to changes, and make data-driven decisions. This integration significantly boosts their operational efficiency and capabilities, turning them into smart machines.

Applications of Robotics

Robotics offers exciting applications in many fields.

In manufacturing, robots take on labor-intensive tasks to streamline production.

In healthcare, they play pivotal roles in patient assistance and surgical procedures, enhancing precision and care.

In exploration and research, robotics tackle hazardous or impossible tasks for humans, pushing the boundaries of what s achievable.

Manufacturing and Assembly

In manufacturing and assembly, robots elevate both efficiency and safety. They handle tasks like welding, painting, and material handling with remarkable speed and precision.

The integration of advanced robotic technologies, such as collaborative robots, or cobots, which work alongside humans to enhance productivity, and automated guided vehicles (AGVs), has redefined traditional production environments.

Take Tesla, for instance; they ve harnessed robotic arms for welding and assembly, leading to astounding reductions in production time and a noticeable boost in product quality.

Fanuc’s painting robots provide uniform coverage while minimizing overspray in automotive production. This exemplifies how automation enhances both aesthetic appeal and functional integrity in manufacturing.

These innovations reduce human error and create safer workplaces by taking on the riskier tasks once handled by human laborers.

Medical and Healthcare

Medical and healthcare robotics transform patient care, utilizing robotic systems for tasks such as surgical assistance, rehabilitation, and monitoring vital signs.

These technologies enhance precision in surgeries through robotic-assisted techniques and enable quicker recovery times for patients. The da Vinci Surgical System exemplifies how surgical robots facilitate minimally invasive procedures, resulting in shorter hospital stays and a reduced risk of infection.

In physical therapy, robotic arms significantly enhance rehabilitation programs by offering consistent and accurate movement guidance.

With telepresence robots, healthcare providers can remotely monitor patients, ensuring that care remains accessible, regardless of location.

This integration of robotics ultimately fosters better health outcomes and enhances the overall patient experience.

Exploration and Research

Robotics holds a pivotal position in exploration and research, employing autonomous robots for data collection in hazardous or inaccessible settings, such as the ocean depths or outer space.

These sophisticated machines provide unmatched advantages in scenarios where human involvement would be perilous or impractical. For example, underwater drones, or remotely operated vehicles (ROVs), investigate marine ecosystems and assess underwater infrastructure.

Similarly, NASA’s Mars rovers meticulously examine the Martian soil and climate, searching for signs of life. The ability of these autonomous robots to thrive in extreme conditions boosts research efficiency and empowers scientists to collect valuable data over extended periods.

This exciting technology paves the way for groundbreaking discoveries about our universe.

Frequently Asked Questions

What is Robotics?

Robotics is a technology field focused on robots. It combines mechanical engineering, electrical engineering, and computer science.

What are the basic components of a robot?

The basic components of a robot include a mechanical structure, sensors, actuators, and a control system.

The mechanical structure provides the physical framework for the robot. Sensors gather information from the environment, while actuators are responsible for the robot’s movement. The control system tells the robot what to do based on sensor data.

What are the different types of robots?

There are various types of robots, such as industrial robots, service robots, medical robots, and military robots.

Industrial robots are used in manufacturing processes. Service robots perform tasks like cleaning and security, while medical robots assist in healthcare settings. Military robots are utilized for reconnaissance and bomb disposal.

What is the role of programming in robotics?

Programming is crucial because it allows robots to perform specific tasks and respond to different situations.

Robots can be programmed using languages like C++, Python, and Java. Programmers use algorithms to design the robot’s behavior and movements.

What are the benefits of exploring the basics of robotics?

Diving into robotics opens up a world of discovery! You’ll learn how robots operate and their exciting applications.

It helps develop problem-solving and critical thinking skills and introduces potential career paths in robotics.

What are some common misconceptions about robotics?

One common misconception is that robots are designed to replace human workers.

In reality, robots perform dangerous or repetitive tasks, freeing up humans for more complex and creative work. Another misconception is that robots always resemble humans, but they actually come in various shapes and sizes based on their intended purpose.