The Basics of Supply Chain Management Explained

Supply Chain Management (SCM) is an essential element of contemporary business, impacting every stage of product delivery, from sourcing raw materials to reaching the end consumer.

This article delves into what SCM truly entails, highlighting its importance for your business while outlining the key components that contribute to its effectiveness.

It also tackles the common challenges you may face in this field and shares best practices to elevate your efficiency.

It also examines emerging trends and technologies that are shaping the future of supply chains. Explore with us to uncover the essentials of SCM and its profound impact on today s marketplace.

Contents

- Key Takeaways:

- What is Supply Chain Management?

- The Importance of Supply Chain Management

- Challenges in Supply Chain Management

- Best Practices

- Key Components of Supply Chain Management

- Challenges in Supply Chain Management

- Best Practices for Effective Supply Chain Management

- Future Trends in Supply Chain Management

Key Takeaways:

Supply Chain Management is the coordination and management of all activities in the process of creating and delivering a product or service to the end customer.

Effective Supply Chain Management can lead to increased efficiency, cost savings, and improved customer satisfaction for businesses.

The key components of Supply Chain Management include planning, sourcing, making, delivering, and returning, with the goal of streamlining and optimizing the entire process.

What is Supply Chain Management?

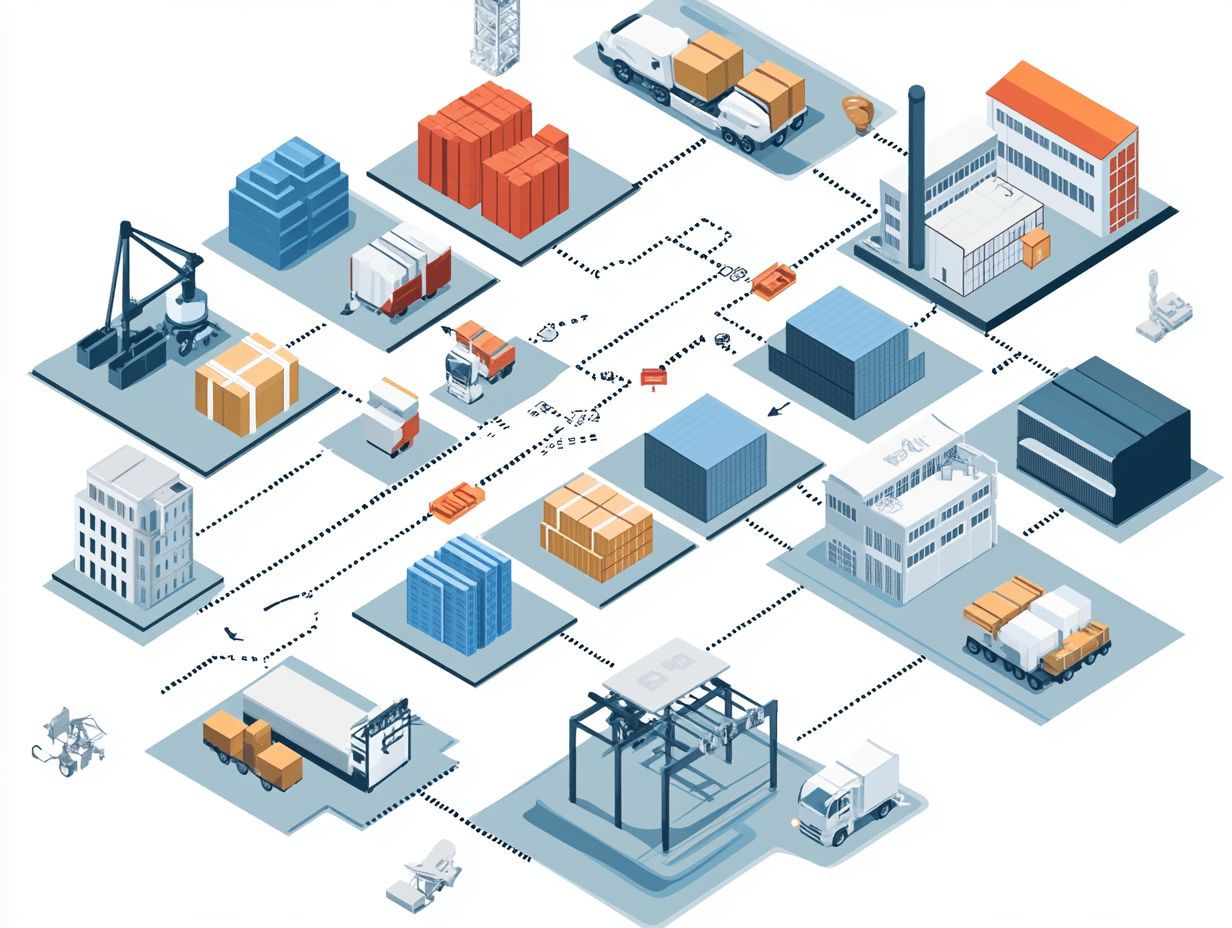

Supply chain management (SCM) is a complex and dynamic process that requires meticulous coordination of a variety of tasks. From sourcing raw materials to overseeing manufacturing, managing inventory, and ensuring that products are delivered on time, every step is vital for achieving customer satisfaction.

SCM encompasses the entire operational spectrum, including the process of managing how resources are acquired, stored, and transported, fostering supplier relationships, and handling returns, all with the goal of optimizing the flow of goods and services.

In today s competitive global marketplace, mastering effective SCM is paramount for your business. It helps you quickly meet customer needs and market demands while minimizing waste and enhancing overall efficiency. Embracing these principles will set you apart and drive your success.

Defining the Concept

The concept of supply chain management is all about strategically coordinating business functions and processes across various companies to elevate efficiency and effectiveness.

This intricate system showcases the seamless movement of goods and information from suppliers to consumers, highlighting just how interconnected logistics and operations truly are.

By mastering effective supply chain management, you can optimize your workflows, ensuring that your inventory levels are just right while minimizing lead times.

Fostering a robust flow of information among all stakeholders enables you to respond swiftly to market demands, creating a competitive edge that s tough for others to replicate.

It’s this synergy between procurement, production, and distribution that ultimately propels growth and enhances customer satisfaction.

The Importance of Supply Chain Management

In today s dynamic business landscape, effective supply chain management is essential for maintaining a competitive edge and delivering exceptional customer satisfaction.

By seamlessly integrating logistics and leveraging advanced technology, you can enhance operational efficiency and streamline processes, positioning your organization for sustained success.

Benefits for Businesses

Effective supply chain management offers a wealth of benefits for you and your business, from heightened customer satisfaction to improved manufacturing efficiency and seamless operations.

By optimizing your demand planning, you can accurately forecast customer needs, which minimizes both stockouts and excess inventory. This leads to significant inventory optimization, allowing you to allocate resources efficiently to meet market demands, ultimately reducing waste and cutting costs.

A robust returns process enhances your business’s resilience, enabling swift handling of returns and fostering customer loyalty.

Effective supply chain management also plays a crucial role in supplier performance, enabling you to maintain strong relationships with your suppliers, thereby ensuring the quality and timeliness of deliveries.

Altogether, these elements contribute to a more sustainable and responsive supply chain, positioning your business for lasting success.

Challenges in Supply Chain Management

While SCM offers numerous benefits, it also presents challenges that businesses must navigate effectively.

Best Practices

Implementing best practices in SCM can further enhance your operational capabilities and customer satisfaction.

Consider how you can apply these SCM concepts in your own business to drive success.

Key Components of Supply Chain Management

Key components of supply chain management encompass vital processes like inventory management, demand planning, production cycles, and product flow.

Together, these elements work harmoniously to guarantee seamless operations from suppliers directly to customers.

Overview of the Process

The supply chain management process involves essential activities that transform raw materials into delivered products. This journey highlights how effective logistics are crucial. It also shows how optimal inventory levels impact production cycles.

Every phase ranging from procurement to warehousing and distribution plays a pivotal role in meeting customer expectations and ensuring timely product delivery.

By employing efficient models throughout these stages, you can streamline operations, reduce delays, and enhance overall performance. Understanding the nuances of predicting customer needs enables your organization to adapt swiftly, ensuring that resources are allocated effectively to meet evolving market needs.

Challenges in Supply Chain Management

In the realm of supply chain management, you’ll face many challenges in the global marketplace.

Issues such as product recalls, waste management, and fluctuating demand can significantly impede your operational efficiency.

Common Obstacles and How to Overcome Them

Common obstacles in supply chain management often manifest as inefficiencies in logistics, poor inventory management, and a lack of visibility throughout the supply chain.

These challenges can significantly increase waste, ultimately hindering your overall manufacturing efficiency and affecting your company s bottom line.

To address these issues, leverage advanced technology, such as real-time tracking software, which enhances transparency and enables better decision-making.

Improving communication among all stakeholders from suppliers to retailers is essential for ensuring alignment and facilitating a smoother flow of information.

Building strong relationships with suppliers fosters collaboration on waste reduction strategies, leading to a more efficient and sustainable supply chain.

Best Practices for Effective Supply Chain Management

By implementing best practices in supply chain management, you can significantly elevate manufacturing efficiency, minimize waste, and seamlessly align your operations with sustainability initiatives and lean SCM principles.

Tips for Improving Efficiency and Productivity

To elevate efficiency and productivity in supply chain management, embrace best practices like continuous flow models and data analysis to make informed decisions.

By leveraging technology integration, you can streamline processes and enhance communication, allowing for quicker responses to market fluctuations. Implementing advanced software solutions enables real-time tracking and improved forecasting, which can significantly minimize operational disruptions.

Prioritizing waste management strategies not only cuts unnecessary costs but also aligns with sustainability goals that resonate with today’s conscientious consumers.

Building strong supplier relationships fosters collaboration and trust essential elements for gaining a competitive edge and ensuring consistent customer support, ultimately driving your success and long-term growth.

Future Trends in Supply Chain Management

You stand at the forefront of a transformative era in supply chain management, where advancements in digital technology and supply chain analytics are reshaping the landscape.

As you embrace these innovations, a keen focus on sustainability practices will position you to meet the evolving expectations of your customers, ensuring your operations not only thrive but also contribute to a better future.

Innovations and Technologies Shaping the Industry

Innovations and technologies are transforming supply chain management. Automation and digital transformation are paving the way for more efficient operations.

This shift is driven by new developments in artificial intelligence, blockchain, and the Internet of Things (IoT). These technologies enhance visibility and flexibility in your supply chain.

With AI analyzing real-time data, you can quickly anticipate and respond to demand shifts. This minimizes potential disruptions.

Blockchain technology offers a secure digital ledger that tracks transactions. It ensures that products are authentic and traceable, which is vital for sustainable practices.

IoT devices allow seamless communication among stakeholders. This leads to better inventory management and reduced waste.

By integrating these cutting-edge technologies, you secure a competitive edge and align operations with environmentally responsible practices.

Frequently Asked Questions

What is supply chain management?

Supply chain management is the process of managing the flow of goods and services from origin to consumption. It coordinates activities of suppliers, manufacturers, distributors, and retailers to ensure timely delivery of products.

What are the key components of supply chain management?

The key components include planning, sourcing, manufacturing, delivery, and returns. They work together to ensure smooth flows of goods and services.

What are the benefits of effective supply chain management?

Effective supply chain management reduces costs and improves customer satisfaction. It also increases efficiency and enhances competitive advantage.

What are some common challenges in supply chain management?

Common challenges include managing inventory, forecasting demand, and maintaining supplier relationships. Transportation and global supply chain management can pose additional difficulties.

How does technology impact supply chain management?

Technology enables real-time data tracking and improves communication. It also automates processes and optimizes inventory management.

What are some best practices for supply chain management?

Best practices include building strong supplier relationships and implementing visibility and transparency. Utilize data analytics and foster a culture of collaboration and innovation.